Digital

The Power of Data

IDEA Digital Platform

As part of our ambition to share Imodco full lifecycle expertise and to unlock the power of data; we are pleased to offer our IDEA digital platform. IDEA and its associated web-based portal, is an operation & integrity management solution that enables operational teams to work remotely and efficiently, having all true information of the asset stored and easily accessible, from both computer & mobile.

01 Project Files

02 Maintenance

03 Spare Parts

04 Tutorials

05 Oil & Grease Monitoring

06 Real time monitoring

Digital Experience

“Embrace latest digital technologies across the entire product life cycle to improve performance of Imodco current systems, lower the cost of our products through more efficient execution, and create a strategic direction towards a fully digital future.”

Director’s Message

Technologies

Imodco Telemetry

Automation, instrumentation and telemetry technologies have been constantly improving in order to meet the high expectations of the evolutive market.

Imodco decided to develop 2 In-House solutions of telemetry systems to allow loading/offloading operations in the most constraining configurations.

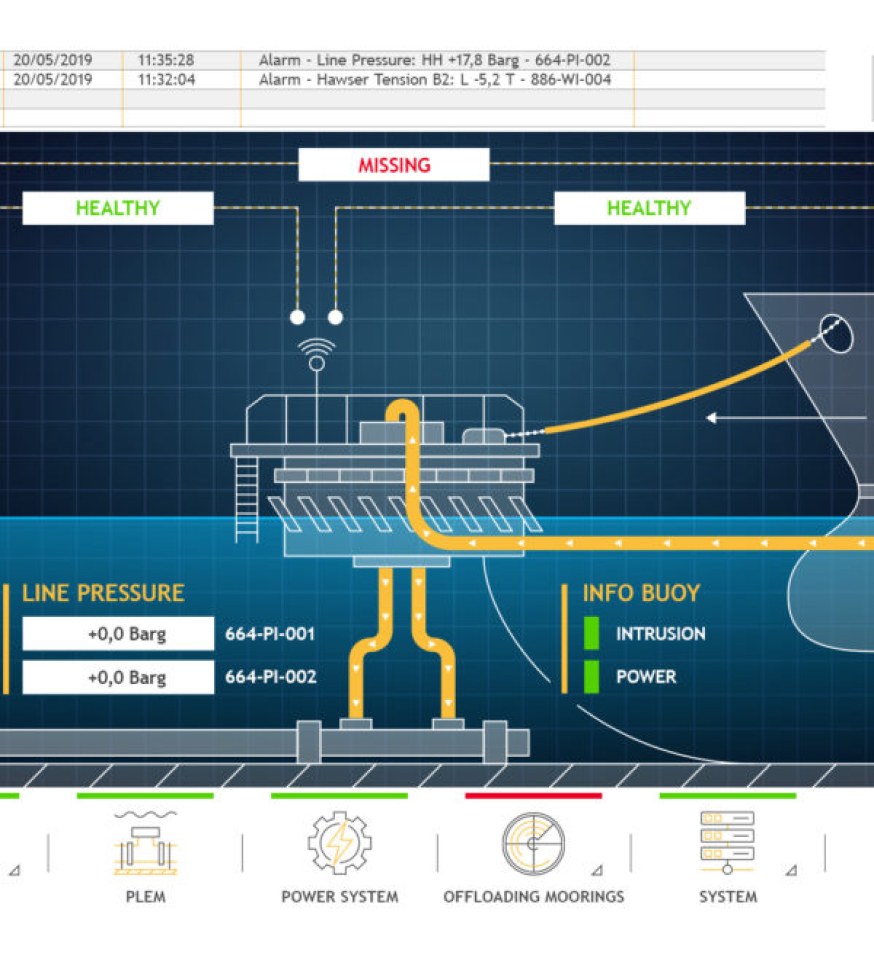

Based on Imodco experience and feedback from operators, Imodco In- House XL Telemetry system allows remote control and monitoring of PLEM valves ensuring safety and quality during operation for all the new build and “in service” CALM systems.

Imodco In-House 3C Telemetry system has been developed to control and monitor hawser tensioning system and process instruments of the buoy. The 3C telemetry allows to measure the state of the system in real time. Data are collected and displayed on a tablet and simultaneously sent via 4G network to a protected cloud.

Imodco In-House Telemetry products are imagined, developed and built to PROTECT people, environment & client assets.

Typical Equipment

- PLEM values remote control & monitoring (XL Telemetry only)

- Standalone solar power system

- Navigation aids

- Marine

- Foghorn

- Data transfer to secured cloud via 4G network (T3C only)

- Navigation aids

- Standalone equipment

Instrumentation

- Mooring hawsers tension

- Hawser load alarm

- Flashing beacons

- Pressure/temperature transmitters

- Level transmitters

- Swivel leak detection

- Gas detector

Benefits

- Inhouse Imodco technology

- User friendly interface

- Control of obsolescence of the equipment

- Adaptable design

- Proven technology

- High reactivity for aftersales service